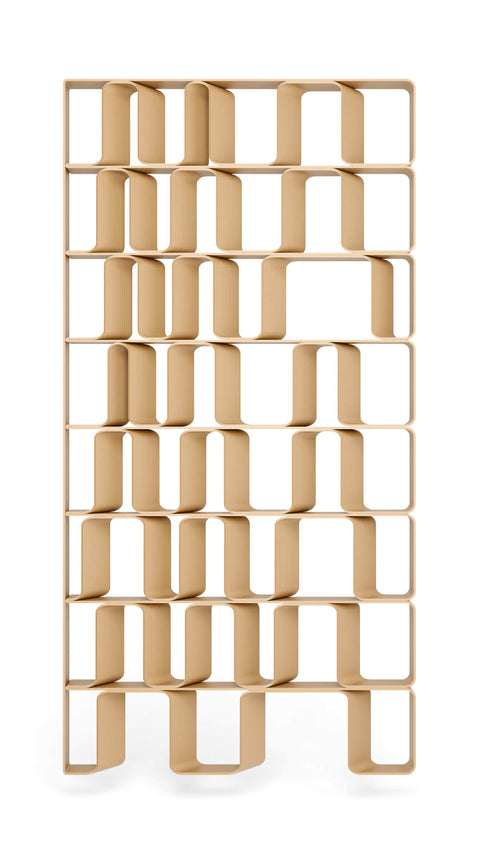

3D TIŠTĚNÉ MODULÁRNÍ PANELY

Společný projekt s 3D tiskovým labem Voxell přinášíme velkoformátovou aditivní výrobu do oblasti interiérového designu. Naším cílem je spojit estetiku a funkčnost s pokročilou technologií 3D tisku a nabídnout tak architektům a designérům novou platformu pro kreativní práci. Výsledkem této spolupráce jsou modulární panely, které obohacují interiéry o jedinečné funkční prvky.

Spolupráce:

VOXELL

Materiál:

DŘEVĚNÝ KOMPOZIT

Fotografie:

MARTIN ŽAMPACH

Umístění:

BRNO/PRAHA

„Jako produktový designér jsem se vždy snažil kombinovat estetiku a funkčnost s inovativní technologií. Chtěl jsem vytvořit produkt, který by nebyl jen estetickým prvkem interiéru, ale také odrazem možností, které nám dnes 3D tisk nabízí. Aditivními technologiemi se zabývám již přes deset let a stále mě fascinují obrovské možnosti posouvání hranic výroby a designu. 3D tisk vnímám jako vysoce efektivní technologii pro tvorbu jak finálních produktů, tak soliterních objektů do interiéru. Výhodou 3D tisku je flexibilita a snížení odpadu při samotné výrobě.“

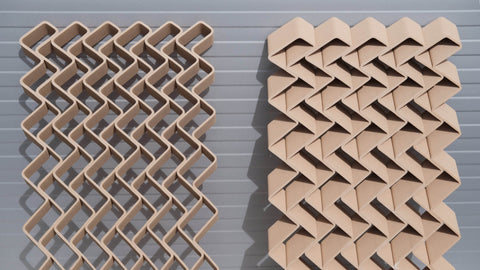

Modulární panely představují flexibilní řešení pro vnitřní příčky nebo stěnové panely. Pomocí velkoformátového 3D tisku umožňují vytvářet opakující se vzory a komplexní, zakázková řešení s minimálním odpadem. Panely mohou sloužit jako dělicí stěny nebo prvky, které dodávají interiéru jedinečný vzhled, a charakter.

Panely jsou navrženy tak, aby maximálně využily výhody velkoformátového 3D tisku – od efektivity designu, přes tisk z recyklovatelných kompozitů, až po minimalizaci odpadu prostřednictvím zakázkové výroby.

Efektivita výroby je pro mě jako designéra klíčová. Díky 3D tisku můžeme výrobní proces zrychlit na minimum a tisknout pouze to, co je skutečně potřeba – finální produkt. Tento přístup minimalizuje nejen náklady, ale i odpad, což je pro mě jako designéra, který se zaměřuje na udržitelnost a uzavřené životní cykly produktů, klíčové. Opakující se vzory umožňují architektům nebo jiným designérům experimentovat. Pomocí algoritmů lze vzory dále posouvat a společně testovat hranice 3D tisku a tvarového designu. Modularita pak vytváří dostupnější řešení pro jakýkoli projekt interiérového designu. Tisk s granulemi umožňuje použití recyklovaných a recyklovatelných materiálů. Věřím, že tímto způsobem posuneme 3D tisk od prototypování více k tisku finálních produktů a snížíme zbytečný odpad.